vickers hardness test advantages and disadvantages|vickers hardness testing procedure : discount store What are the Advantages and Disadvantages of the Vickers Method? Vickers hardness test can measure forces outside of the ISO-specified HV 0.01, HV 1, and HV 10 ranges. This ensures . December 16, 2022. Genre: Action-Adventure, Fantasy, Science Fiction. "Avatar: The Way of Water" reaches new heights and explores .

{plog:ftitle_list}

webJogue Roiworld dress up games diretamente no Site de Jogos Online Gratis. Os melhores e mais novos Jogos de Roiworld dress up games 100% grátis.

The Vickers hardness test has the given advantages: The Vickers hardness test can measure the entire range of hardness values as it can evaluate all the materials and samples used for the test, whether they are soft or hard in texture.

What are the Advantages and Disadvantages of the Vickers Method? Vickers hardness test can measure forces outside of the ISO-specified HV 0.01, HV 1, and HV 10 ranges. This ensures .

The Vickers Hardness Test is particularly suitable when: You need accurate and reliable hardness measurements across a wide range of materials. You’re working with materials that have varying hardness levels, .

Advantages and disadvantages of hardness testing using the Vickers test method. The Vickers method offers the following advantages: The Vickers method can be used with any and all materials and test specimens, from soft to hard, .

Advantages and disadvantages of the Vickers method. The Vickers method has the following advantages: The Vickers method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the .

Vickers hardness testing is vital in assessing critical parts' hardness and wear resistance, such as engine components, gears, and turbine blades. This ensures the reliability and safety of these components under extreme operating . Despite its limitations, the Vickers hardness test is one of the more reliable hardness testing procedures to date. Its wide scope of application and the ease of maintenance for its testers make the test a viable addition to . Reporting. Advantages of Vickers Hardness Testing. Versatility: The Vickers test can be applied to a wide range of materials, from very soft to extremely hard, without altering the test procedure significantly.Non-destructive: Apart from the visible indentation, the Vickers test does not cause significant damage to the material, allowing for reuse. This feature is advantageous for minimizing waste and optimizing test materials in a testing .

1. 0. Bookmark (0) Hardness Testing of Metals: Rockwell, Brinell, Vickers, Knoop, and Leeb Tests. This article provides an overview of common hardness testing . Advantages: Disadvantages: Applications: Load Range (kgf*) Indentation Type: Standards: Rockwell C (HRC) Metals, Alloys: . Vickers Hardness Test. The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to hard ceramics, and is especially valuable for micro hardness testing requiring .The Knoop method has the following advantages. The Knoop method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the entire hardness range. There is only one type of indenter, which can be used for all Knoop methods.

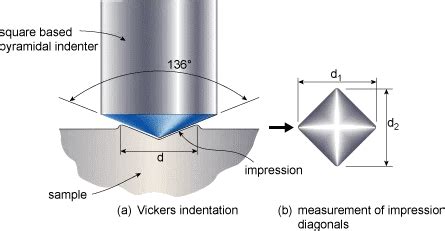

What are the Advantages and Disadvantages of the Vickers Method? Vickers hardness test can measure forces outside of the ISO-specified HV 0.01, HV 1, and HV 10 ranges. This ensures that any sample object of a given hardness can be tested. The Vickers hardness test is the most versatile of all the available procedures.Hardness test: The hardness test is a type of mechanical test used to check the material properties. It helps to eliminate the chances of failure of a specimen before its use. A hardness test can be categorized as a micro and macro hardness test. The types of macro hardness tests are the Rockwell hardness test, the Brinell hardness test, and .Vickers hardness testing to ASTM E92 is a hardness test method with optical evaluation in which the size of the indentation left on the surface of the test material by a pyramid-shaped diamond indenter (square base and interfacial angle of α = 136°) is measured. The test load is applied precisely and the diagonals of the indentations are used to calculate the Vickers .The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test force >= 49.03 N), more precisely with a test force of 29.42 to 1471 N. It is a differential-depth method.

The hardness of metals can be tested by 12 different hardness tests and the Brinell Hardness test is the oldest technique to measure the hardness of metals but is widely used. In this blog, we will discuss only Brinell Hardness test methods, including principle and theory, applications, advantages and disadvantages.

Carton Puncture Tester distribute

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals. ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials.

The Rockwell, Brinell, and Vickers hardness testing methods are generally used for different scenarios and situations. However, hardness testing professionals have sometimes found it hard to agree on the most suitable method based on their differences. . Related Article: What are the Advantages and Disadvantages of the Vickers Method? .The Leeb method is a quick and portable hardness test method, which is determined by the ratio of rebound velocity to the impact velocity of a moving impact body. It is best applied to solid parts of the object for example casting and forgings. In the article, we include the advantages and disadvantages of Leeb method in details.

vickers hardness testing procedure

In certain cases, Rockwell offers compelling advantages. Fast, rough, affordable, and less surface treatment represent some of the key descriptors of this testing method. Rockwell is the most common procedure and offers accurate results. . The Vickers hardness testing method offers advantages such as a small indentation size, accurate .Advantages of Brinell Hardness Test. Simple setup and operation – The Brinell Hardness Test is easy to set up and use, making it accessible for various users without the need for extensive training.; Wide material applicability – It works on a variety of materials, including soft metals and alloys, broadening its usability across different industries. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use another hardness test on it. There are two methods to perform the Brinell hardness Test on the metal as follows: Standard Method; Non-Standard Method; Standard Brinell .

While Vickers hardness testing is versatile and widely used for metallic materials and general-purpose testing, Knoop hardness testing excels in evaluating brittle materials and surface coatings. By understanding the differences between these two tests and their respective advantages, metallurgical engineers can make informed decisions about .The Vickers hardness test is a very reliable method for measuring the physical properties of materials. It is a very popular method in engineering, industrial use, and the oil and gas industries. The article is all about the principle and application of Vickers hardness test. . Related Article: What are the Advantages and Disadvantages of the .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find .Due to this shallow indentation depth, the Knoop method is particularly suitable for testing very thin layers (e.g. aluminium foil). Due the long and narrow (elongated) test indent, the Knoop method is best suited for use with small, .

The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness. . Leeb Hardness Test. Leeb hardness testing is a dynamic test, it uses a impact device to generate a force on the material. A sensor on the material measures the rebound velocity and the hardness value is calculated based on the velocity and the impact device properties. The advantage of Leeb testing is that it can be used to test hard materials .Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.

The advantages and disadvantages of the two test meth-ods come principally from the differently shaped indenters. Vickers testing uses a pyramidal diamond (Fig.1) resulting in . and the average of those two values is used in the calculation of hardness. Knoop testing uses an elongated pyramidal indenter (Fig.2), producing a rhombus-shaped . Therefore, hardness values can only be compared if they have been obtained by identical test procedures. The most important procedures and their advantages and disadvantages are explained in more detail below: Brinell hardness test (explained in this article) Vickers hardness test; Rockwell hardness test Advantages and disadvantages. The advantage of Rockwell hardness testing is the relatively short testing time and good automation capability, as the measured values are determined directly from the indentation depth without optical measurement under a microscope. This process is therefore particularly suitable for automated production.

Vickers hardness testing has been widely used as one of the basic and reliable material test methods. Furthermore, triangular pyramidal indentation technique (the nanoindentation method) is also used to analyze the mechanical characterization of extremely thin films. In order to measure the true hardness of coatings, it is important to find the . Vickers Hardness Testing, named after its creator Robert L. Smith Vickers, is a method that has stood the test of time for its precision and versatility in assessing hardness. . Advantages of Vickers Hardness Testing. Versatility: The Vickers test can be applied to a wide range of materials, from very soft to extremely hard, without altering . The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that .

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .

vickers hardness testing machine price

vickers hardness testing machine diagram

13 de mai. de 2023 · Resultado da Lotofácil 2811 de hoje, 13/05; prêmio é de R$ 1,7 milhão. Confira as dezenas sorteadas. Escrito por A. Seraphim , 18:30 - 13 de Maio de .

vickers hardness test advantages and disadvantages|vickers hardness testing procedure